KCT 8 BALL

BALL TRANSFER OVERVIEW

KCT Ball Transfer Units provide a perfect material handling solution where loads need to be moved in multiple directions either end of line or in-part of a system in a smooth, accurate motion with minimum operator assistance without the requirement for a powered conveyor.

Ball transfer tables can reduce the need for unnecessary lifting and positioning of products, which can result in operator stain or injury. They form a key end-of-line solution on process improvement and the overall health and safety of staff, by in some cases, eliminating the need for heavy lifting.

With many variations available, at KBR Conveyor Sections, we can provide a range of suitable transfer table options to suit your requirements.

Heavy-duty or light-weights ball transfer units are available with various fitting styles and ball positions, from fixed units, drop-in and retained ball units, elevated ball units.

Our ability to manufacture a range of custom ball transfer tables enables our product to be used in a wide range of industries including and applications related to general material handling systems including order picking, assembly lines, feeding machines, steel tube & steel sheet handling, press tooling and glass handling to name a few.

By custom manufacturing unique ball table designs, we are unrestricted in our design approach, putting your companies needs and requirements first.

BALL TABLES

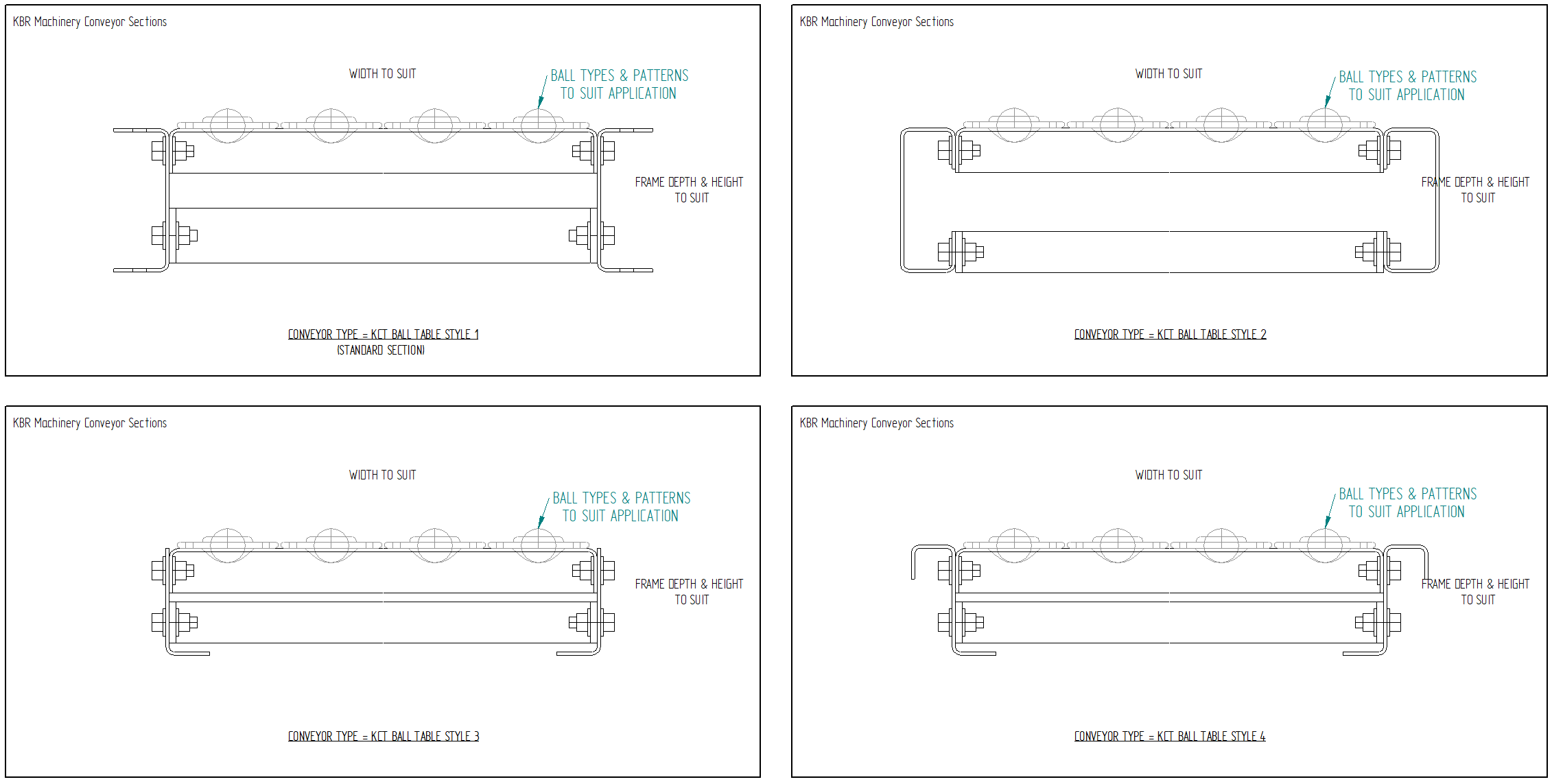

We offer four standard frame styles, in which to set our ball transfer tables into a supporting frame. Section sizes can be adapted to fit within current system designs, in many circumstances, we are able to match sections to suit existing equipment at the upmost economical expense.

Our approach to the table design is to create a strong, durable and robust table, built to last with the assurance that our equipment is a UK manufactured product, built in our own production facility, where we can monitor quality for the beginning.

Ball transfer inserts can be supplied as table insert only, guided stops and ball channels, to be added to pre-existing conveyors for improved material handling.

Ball Units

Ball Transfer Units are a multidirectional, material handling system manufactured from high-quality materials including stainless steel, mild steel supplied bright zinc plated, or a mixture of each material with a nylon ball unit.

They consist of a large load-bearing ball which sits upon many small balls encapsulated in a hemispherical cup. The housing can contain a seal to clean the load ball as it rotates. The design greatly reduces friction and allows heavy loads to be moved with a minimum of effort.

Efficiency Unveiled: A Comprehensive Guide to Understanding Ball Conveyors

Introduction to Ball Conveyors: Innovative material handling solutions designed for seamless and efficient transportation of goods within various industries.

Essential Components: Consists of strategically placed spherical balls on the conveyor surface, enabling smooth movement in any direction.

Flexible Movement Mechanism: Unlike traditional conveyors, enables multidirectional movement, offering increased flexibility in material handling.

Applications Across Industries: Widely used in manufacturing, distribution, and logistics due to their efficient handling of diverse products.

Considerations, Maintenance, and Integration:

Material Compatibility: Choosing the right ball material is crucial for optimal performance.

Regular Maintenance: Periodic inspection and cleaning ensure smooth operation and longevity.

Integration with Other Systems: Seamlessly integrates with sorting devices, packaging machinery, and automated systems.

Future Trends and Innovations: Ongoing advancements introduce features such as smart controls, real-time monitoring, and improved energy efficiency.

Advantages of Ball Conveyors: Optimizing Material Handling Efficiency

Ball conveyors offer a range of advantages that make them a preferred choice in various industries:

- Versatility:

- Suitable for a diverse range of products, from small packages to larger items, showcasing adaptability in handling various materials.

- Reduced Friction:

- The ball mechanism minimizes friction, ensuring a gentle and smooth transport process that is particularly beneficial for delicate or fragile items.

- Space Optimization:

- Ideal for applications with limited space, ball conveyors provide a compact and efficient solution, making the most of available workspace.

- Customization Options:

- Ball conveyors can be tailored to specific industry requirements, offering bespoke solutions that align with the unique needs of different applications.

- Enhanced Efficiency:

- Ball conveyors facilitate quick and efficient sorting, diverting, and accumulation of items, contributing to streamlined material handling processes.

In conclusion, the dynamic functionality and inherent advantages of ball conveyors position them as valuable assets in modern material handling operations. Their multidirectional movement, reduced friction, space optimization, customization options, and efficiency enhancements make them a versatile choice across various industries.

Deciphering Precision: A Guide to Choosing the Optimal Ball Spacing for Your Ball Conveyor

Welcome to our comprehensive guide on selecting the optimal ball spacing for your ball conveyor – a critical aspect that significantly influences the performance and efficiency of your material handling system. When choosing ball conveyors, it is paramount to carefully consider the spacing and ball type for various reasons, as these factors play a pivotal role in ensuring smooth and effective transportation of your products.

Understanding the Importance of Ball Type and Spacing:

The choice of ball type and spacing is not arbitrary; it is tailored to the specific needs of your material handling operations. Our extensive range of ball types, including Nylon, stainless, and BZP Steel, caters to diverse applications – from warehousing to food production and end-of-line machinery. Each ball type is designed to meet the unique demands of different environments, ensuring optimal performance and longevity.

Tailoring Solutions to Your Products:

One size does not fit all when it comes to ball conveyors. The ball type and spacing should be customized based on the products you are handling. This customization ensures that your conveyor system is not only efficient but also aligned with the specific characteristics of the items in transit.

Versatility Across Industries:

Our ball conveyors are versatile, addressing the needs of various industries. Whether you are involved in warehousing, food production, or require end-of-line machinery solutions, our diverse range of ball types ensures that you have the right material for the job.

Calculating the Ideal Ball Pitch:

Determining the appropriate ball pitch is a crucial step in the selection process. We recommend calculating the ball pitch as 3.5 times the width and length of your products. This calculation, coupled with adherence to a sufficient load capacity, ensures that your ball conveyor operates at its peak efficiency, minimizing the risk of jams or disruptions.

In conclusion, choosing the optimal ball spacing for your ball conveyor involves a thoughtful consideration of ball type, product characteristics, and calculated pitch. This tailored approach guarantees a material handling solution that not only meets but exceeds your operational requirements, contributing to the overall success of your business.

Unlocking Versatility: The Diverse Applications of Ball Transfer Units

Discovering the Wide-Ranging Applications of Ball Transfer Units.

Ball transfer units, versatile in design and functionality, play a pivotal role across various industries, contributing to the seamless movement of materials and enhancing the manoeuvrability of machinery and equipment. Let's delve into the diverse applications of these units and how they are integral to the efficiency of different industrial processes.

1. Conveyor Systems: Navigating Smooth Material Flow Ball transfer units find a crucial application in conveyor systems, ensuring the smooth and efficient flow of materials. By providing omnidirectional movement, these units contribute to the flexibility and adaptability of conveyor setups, allowing for quick and precise material handling.

2. Assembly Lines: Enhancing Precision and Efficiency In assembly lines, precision is paramount. Ball transfer units facilitate the easy rotation and movement of components, improving the overall manoeuvrability of the assembly process. This not only enhances efficiency but also minimizes the risk of errors during product assembly.

3. Automated Storage Systems: Optimizing Space and Accessibility The automation of storage systems demands solutions that optimize space and accessibility. Ball transfer units come into play by providing a dynamic and adaptable surface, enabling the smooth transfer of goods within automated storage setups. This ensures a streamlined and space-efficient storage process.

4. Mechanical Engineering: Maneuvering Machinery with Ease In the realm of mechanical engineering, the manoeuvrability of machines and equipment is critical. Ball transfer units serve as valuable components, allowing for easy and precise movement. Whether it's adjusting the position of heavy machinery or enhancing the mobility of industrial equipment, these units contribute to smoother operations.

Conclusion: Harnessing the Power of Ball Transfer Units From conveyor systems to assembly lines and beyond, the application of ball transfer units spans across a diverse spectrum of industries. Their versatility in enhancing manoeuvrability, precision, and efficiency makes them indispensable in the seamless functioning of industrial processes. Explore the possibilities of integrating ball transfer units into your operations to unlock a new level of versatility and performance.