KCD-50

Conveyor Overview

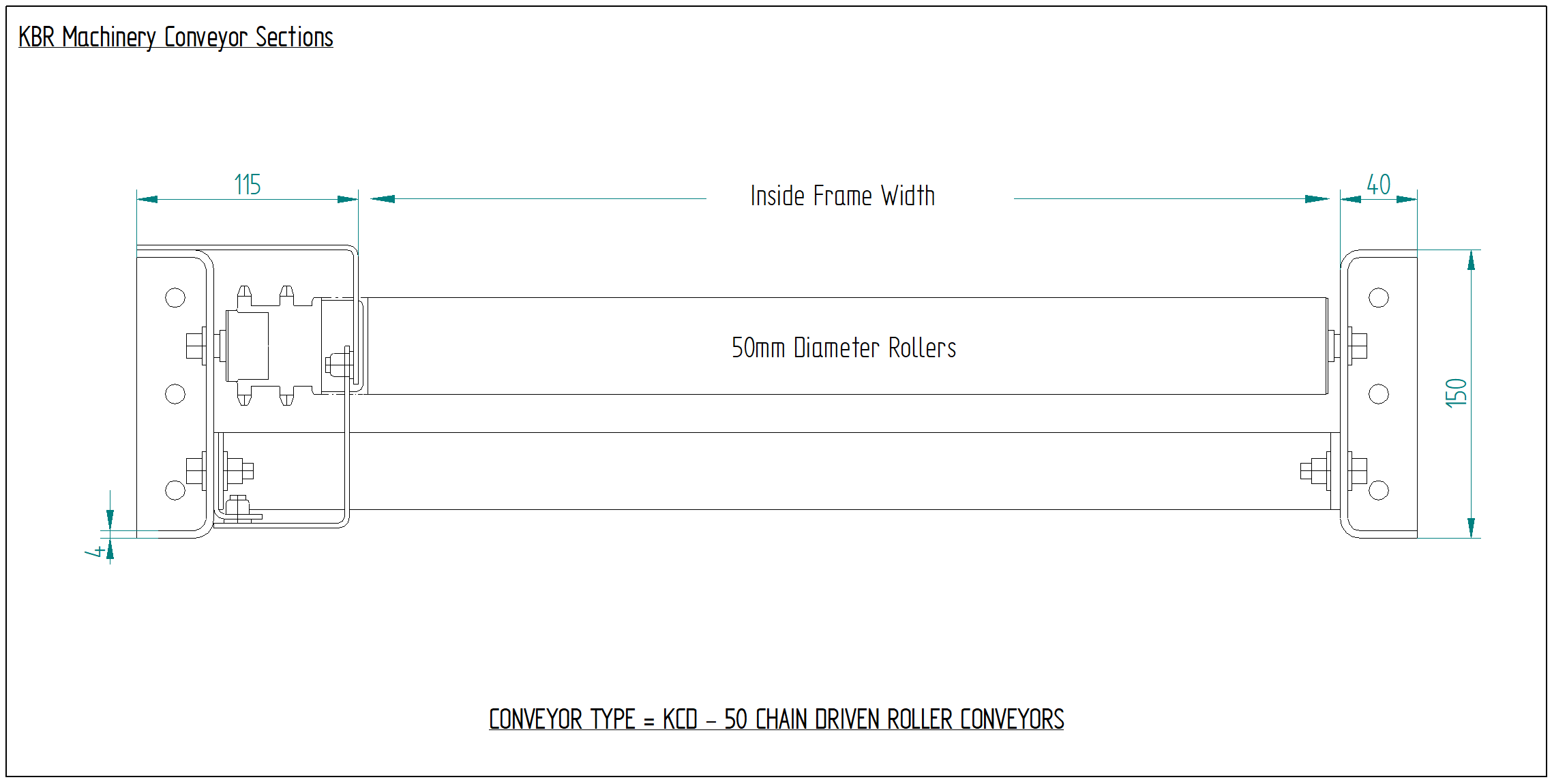

The KCD chain driven roller conveyor is a heavy-duty, robust conveyor module. Manufactured from high gauge folded mild steel, the KCD chain drive is built for harsh and arduous working environments.

Roller systems with chain-driven rollers are ideal for moving heavy and bulky packages.

What are some of the advantages?

Build Quality at a Glance

Conveyors are manufactured using 150mm frame profiles. 4mm mild steel is the material of choice for this conveyor offering extreme durability for the toughest of environments.

Sections are supplied fully guarded overall mechanisms including chains & drive units for added operator safety and aesthetics.

Featuring solid fully welded double simple 1/2 inch sprocket rollers, supplied BZP finish as standard or rubber-coated for chemical, oil, and nonmarking applications.

Our conveyors use quality British manufacturing techniques together, with fully folded, durable full steel profile side sections and cable containment for a clean, aesthetic finish.

The KCP roller conveyors can be supplied in 3 standard colors, RAL5002 Ultramarine Blue, RAL 9010 Pure White, RAL 9005 Jet Black. Custom powder coated colors are available.

Industries & Applications

Typical industries include Robotics & Automation, Foundries, Mortuary Systems, Glass Manufacturer, Stone Processing, Heavy-Duty Warehouse, Logistics, Automotive, Assembly Lines.

With a range of drive units available and achievable roller speeds of up to 30 meters per minute, the KCD 50 handles product loads up to 250kgs per linear meter.

Furthermore, our versatile design approach offers features such as built inside guards, Curved Sections & Pneumatic chain transfers enabling endlessly configurable layouts.

Tailor-made custom electrical control options are available for customized conveying applications for example pick and place, indexing, or robot process scenarios.

How do they work?

Driven Chain Conveyors are designed to offer high drive and friction to the products being handled.

Unlike Line-shaft driven rollers, which are designed for accumulation, the high friction allows for heavy loads by giving positive drive power simultaneously to all rollers without loss of power through slipping.

This is all made possible by utilizing precision conveyor rollers, incorporating heavy-duty welded sprockets to each end.

Each sprocket roller is joined in series from one roller to the next to create a single chain-driven zone.

KCD-50 Chain conveyors can be either supplied in single drive zones, for example, applications such as robot placement, where components or assembly pallets need to be placed in a specifically controlled position. Chane conveyors can be fitted with braked drive motors to create an instant stop where required.

Systems can also be built around a single drive unit for lighter weight applications. Each section features a cover plate to one end, by removing this plate we can allow sections to be linked through the chain to chain, creating extended drive zones.

summary

These powered roller conveyors offer high drive power, reliability, durability through a wide range of applications. Conveyors are fully serviceable utilizing common spares and parts, including ease of access cover plates through.

Although heavy-duty, powered driven roller conveyors are adaptable with the potential for including additional sections including straights, drive, curves, and transfers into the system.

This gives flexibility in design for future improvement, where required by our customers.

CUSTOMER SUPPORT

Our conveyors are supplied as standard with a 12 Month Manufacturers Warranty.

Conveyors are supplied fully assembled in single modules.

Some require minimal assembly, and some a little more than the simple assembly. If you don’t think you could manage, or simply want the assurance of a professional installation and demonstration, we can offer an installation service for an extra cost.

To find out how much assembly is required on your conveyor, please contact us.