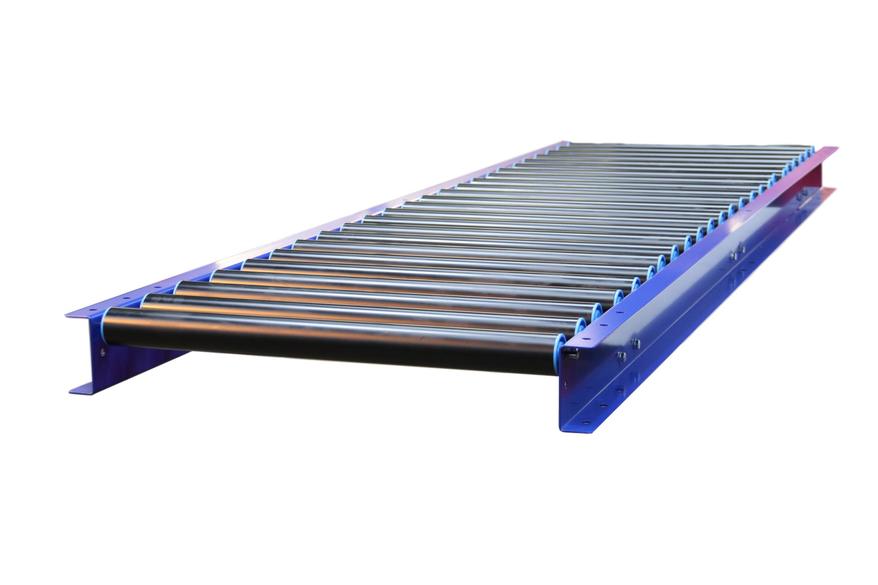

Gravity Roller Conveyors

GRAVITY CONVEYORS - STANDARD PRODUCT RANGE

ROLLER CONVEYOR MANUFACTURERS

We are a conveyor roller manufacturer producing our own range of light and heavy-duty conveyor rollers, from our site in Telford Shropshire.

We have a custom-built manufacturing facility, where we are in control of our own gravity roller conveyor manufacturing, design, steel processing, finishing, and assembling of conveyors from start to finish.

Roller conveyors are the most simple and affordable type of material handling equipment when considering an investment in roller conveyor systems.

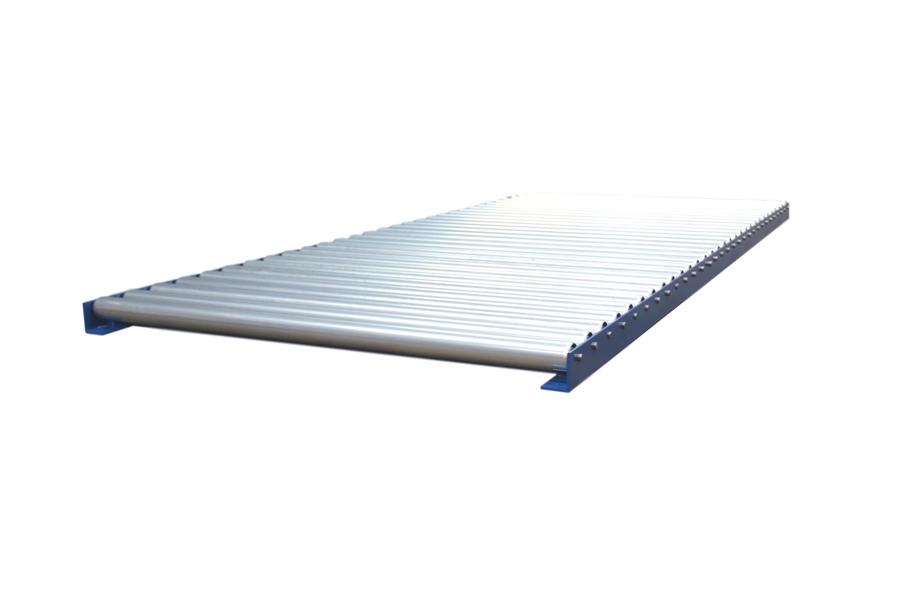

Our KCT roller conveyor range covers a wide range of material handling needs. We produce all types of roller tables from fabricated ball tables to pallet conveyors. Our range of manufactured conveyor tracking and conveyor roller bearings covers a wide range of general material handling needs.

We offer our own range of newly manufactured gravity roller track, along with having the experience to design and build custom gravity roller conveyors to suit more specific applications.

For OEM and equipment resellers, we offer a standard conveyor rollers price list to enable you to quickly and conveniently quote your customers.

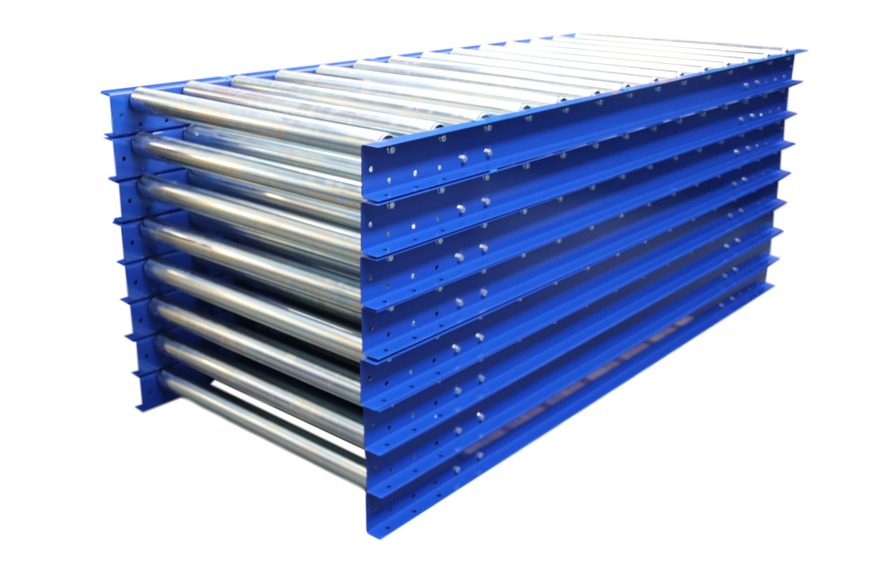

We also carry a range of standard sizes, offering gravity roller conveyors for sale 'off the shelf', as we understand that in some circumstances lead times are critical.

To speak to us about your gravity roller requirements, please contact us.

WHAT IS A ROLLER CONVEYOR

Quite simply put, a gravity roller conveyor is one of the most simple and cost-effective types of material handling, when considering transferring an item from A - B.

Roller track conveyors have many variants, but can easily be adapted to cater for a wide range of material handling needs, thus providing a low-cost handling solution to your business.

Basic gravity roller conveyors work by incorporating a number of 'free-spinning' conveyor rollers. The product in contact with the rollers can then freely roll, on its own accord, or by the aid of an operator.

Typical roller conveyor examples:

- Packing benches

- Removing packed items from an area

- Consolidating products

- Start or end of line accumulation

- Improving productivity

- Eliminating the double handling of products

- Prevention of lifting hazards and operator strain

SELECTING GRAVITY ROLLER WIDTHS AND TRACK LENGTHS

When selecting the correct conveyor rollers for your application, we always recommend considering the following: min/max product size, min/max product weight.

These are two of the most important factors, as it is very easy to select the wrong conveyor type or be misguided into purchasing the wrong type of equipment.

We always recommend that the product traveling on conveyor tracking should fit within the confines of the inside frame width. Although this does happen within certain industries, it is considered hazardous to operate in this way.

The length of the roller conveyor is dependant on the application. When accumulating on a conveyor or creating a 'workflow', it's worth considering the flow rate of products per hour and how quickly an operator can unload the products. A sufficient safety factor should be considered in the time of peak usage of the roller conveyor.

For simple A - B applications, then a general operating length will suffice.

WHAT IS A ROLLER PITCH? WHAT ROLLERS DO I NEED?

The roller pitch is quite simply the distance between the center of one roller to the next. When dealing with a gravity roller track inquiry, the first thing we ask is what roller pitch do you require?

It's worth noting that the roller pitch you choose for any conveyor table will have a significant impact on the cost of the track. Generally, the closer the rollers, the higher the cost.

This is why it's important to consider the maximum and minimum product sizes that will be used on the conveyor. If items are too small for the roller conveyor, it can be an advantage to use totes for smaller products. It is also common to see companies using baseboards for items, to cover a larger surface area.

As a rule of thumb, the product traveling down the length of the conveyor should always be in contact with at least 3 - 4 rollers. This ensures the product will travel smoothly over the conveyor, eliminating the potential of a blockage.

The weight of the product when traveling over the minimum supporting rollers, should not exceed the total capacity of the conveyor rollers in question.

In the above descriptions for our gravity roller conveyors, we provide the information for each roller rating, this can be found in the drop-down menu; 'Roller Details'. It should be noted that the total load rating of the gravity roller conveyor, is also dependant on the roller width and frame type being used.

The wider a roller tube becomes the weight distributed over the roller causes deflection in the material. This means that the conveyor bearings will not be working to their full load capacity.

This can be particularly apparent when using smaller diameter PVC conveyor rollers. To combat this, heavy-duty conveyor rollers can be used with greater tube walls, bearing load capacities, and axle diameters.

If you are unsure about selecting the correct rollers, just ask!

SELECTING SUPPORT STANDS

Once the correct gravity roller conveyors have been selected, it will need to be mounted on a set of suitable support frames.

The support frames should be set out at intervals to suit the weight of the product traveling over the conveyor track. For example; 1 x 2.4m roller conveyor would require 3 x support frames (approx 1.2m intervals).

When using roller conveyors in longer runs, a sharing leg is typically used acting as a join between the sections, this is in addition to a plate bracket or bolted lug.

We can offer frames to provide a natural fall over a required distance. Where distances become too great, powered conveyors should be considered.

The required fall on the roller conveyor will depend on the weight of the product traveling down the conveyor.

The heavier the product, the quicker it will move!

For instances where products are too light for the conveyor, totes or bulk packing should be considered. Where this is not an option, belt conveyor and/or powered roller conveyors should be considered.